The history of containerization

The practice of packing and stacking goods inside large standardized metal boxes and transporting them as distinct, individual units is defined as Containerization. This method of transportation assists trouble-free cargo handling, improved cargo safety, reduced labor and decreased shipping expenditure.

Ever since man began navigating the seas to reach distant lands, he was motivated by a desire to trade goods in exchange for different commodities. Over the centuries, as innovations and mechanization took place, the cargo was carried to ports in sacks, wooden crates and barrels by wagons and trains. Ships were loaded with these bags individually and this method obviously proved laborious and long-drawn-out. For several hundreds of years, this labor-intensive system of handling goods largely remained unchanged. Most of the time, ships remained berthed in ports to load and unload goods rather than sail the seas to transport cargo. While ships remained berthed for extended periods of time, it also led to instances of theft and wastage of time.

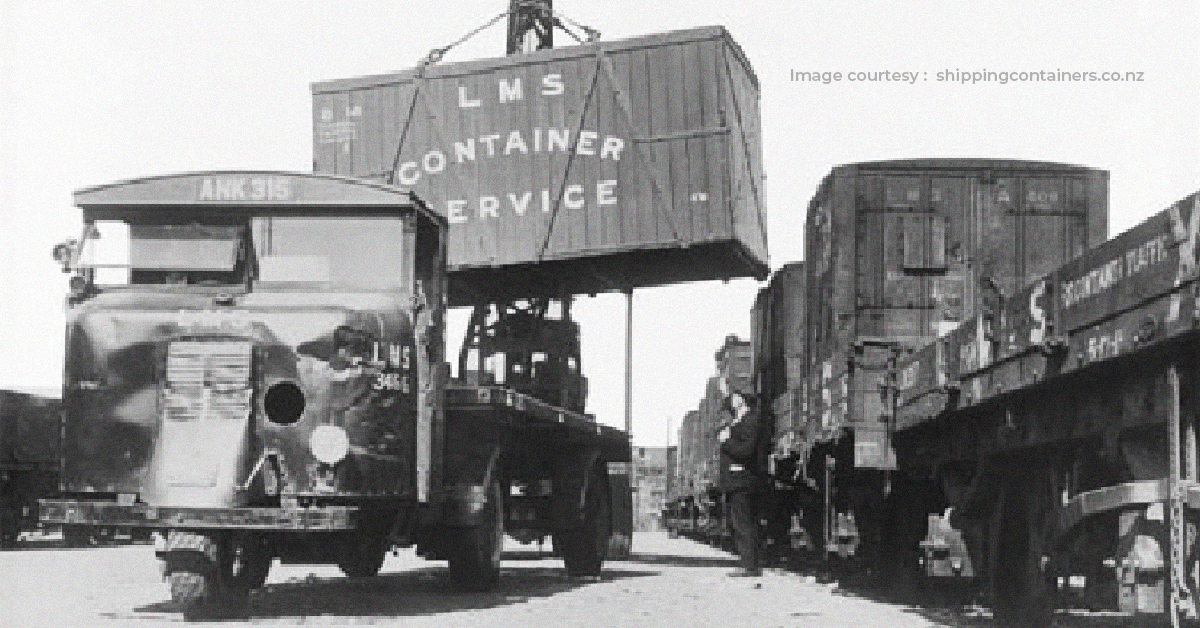

Boxes closely similar to today’s containers were used way back in 1792 for rail and horse-drawn transport in England. During the Second World War, the US Government had used small standard containers for loading and distributing supplies efficiently.

Malcolm P McLean (1914 - 2001) is considered the “father of containerization”. He pioneered the establishment of modern standardized containers and essentially transformed the shipping industry that had remained stagnant and resistant to change for many centuries. In 1955, Malcolm McLean, who had started his career as a truck driver, prospered and went on to own a fleet of trucks, teamed up with mechanical engineer and inventor Keith Walton Tantlinger to design the modern “intermodal container”. The chief attributes they were looking for in these new containers were an innovative design, the durability to support the loading of such enormous metal boxes onto ships, fasten them securely to withstand long voyages in the sea and hassle-free transfer to semi-trailer trucks.

In 2006, modern container shipping celebrated its 50th anniversary. The pioneering maiden voyage took place in April 1956 with a converted oil tanker “SS Ideal X” that carried 58 cargo-laden truck trailers from Newark to Houston. This ship has earned the tag of “the first commercially successful container ship”. Her voyage was closely monitored by industry followers and government officials. At its final destination, the Houston Port, the containers were unloaded and transferred to trailer beds attached to a fleet of trucks. The goods were inspected and found safe and secure. It is no overstatement to claim that the present era’s ever-expanding global international trade is the consequence of that humble beginning under Malcolm P McLean’s leadership. Today, container shipping is one of the strong pillars that supports the burgeoning trade and commercial relations between countries.

Intermodal ocean freight containers are manufactured in standard dimensions that enable them to be loaded, unloaded, stacked and transported over long distances, while also facilitating their smooth transfer from one mode of transport to another, for instance - container ships, rail transport flat cars and semi-trailer trucks. It also eliminates the need to open the doors of such containers.

Ocean freight containers come in the following standard sizes:

| Container Type | Internal Dimensions (L x W x H) | Cubic Capacity |

| 20 Feet General | 5.89 x 2.35 x 2.36m | 33m³ |

| 20 Feet High Cube | 5.89 x 2.35 x 2.69m | 37m³ |

| 40 Feet General | 12.05 x 2.35 x 2.36m | 66m³ |

| 40 Feet High Cube | 12.05 x 2.35 x 2.69m | 76m³ |

Let’s now understand the chief benefits of containerization and how it fuels the growth of the trade and commerce industry in diverse ways:

Standardization: This attribute means that the containers can be handled at any location in the world by way of different modes like ships, trucks and wagons. Every container carries a unique identification and size type code.

Flexibility: There is no restriction on the type of goods that can be transported in a container. Whether it is agricultural, industrial, automobile or perishable goods, containers perform a versatile job. Used containers that have outlived their service life can be refurbished and used for housing site offices or as a temporary shelter.

Economy: Bulk handling of cargo becomes a stress-free task, thanks to automation at ports chiefly centering on dockside gantry cranes that can perform tasks effortlessly unlike conventional methods. Containers can be piled on top of the other in ships, on the ground or on trains and thus reduce the burden on limited space.

Speed and efficiency: It is a proven fact that containerization helps to bring down the time taken for transshipments and reduces port turnaround time from several weeks to a day. This automatically benefits other transport chains involved in moving the containers to their final destination without causing delays.

Warehousing: The need to provide additional insulation and protection to goods from the vagaries of nature is greatly minimized because the containers themselves serve as safe housing for delicate goods.

Security: Shielded from all sides and secured with a lock, the chances of deterioration in quality and theft are greatly reduced.

The bulk of international commercial trade takes place through ships crisscrossing the oceans carrying goods in standardized containers. Containerization has practically revolutionized the shipping industry, and while this standardization is here to stay, we can certainly look forward to more exciting developments in the future as the industry keeps innovating and evolving continuously.

- Log in to post comments